The recent China Solid-State Battery Innovation Summit revealed a critical bottleneck in the development of next-generation batteries: cathode technology, not electrolyte breakthroughs, is the key to making solid-state batteries commercially viable. While electrolytes get attention, the energy density and long-term stability of these batteries hinge on improving the materials that actually store the power.

The Rise of Solid-State: Why Now?

Interest in solid-state batteries has surged for a simple reason: they promise higher energy density, improved safety, and longer lifespans than traditional lithium-ion batteries – all critical for electric vehicles (EVs) and other high-demand applications. Decades of research investment, combined with the urgent need for better battery performance, have pushed the field forward. However, the hype around solid-state batteries overlooks a fundamental challenge: they can’t deliver on their promises without radically better cathode materials.

The Cathode Challenge: Stability and Longevity

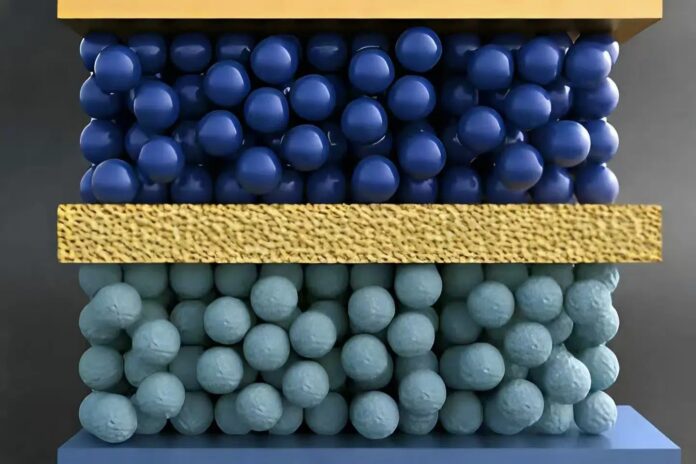

Current solid-state prototypes struggle with interface instability between the cathode and the solid electrolyte. High-nickel cathodes, while improving thermal safety, still degrade rapidly under high voltage or current, forming resistive layers that kill performance within 125 cycles. Even fluorine doping—a common fix—only delays the inevitable. The problem isn’t just chemistry; crystalline cathode materials expand and contract, creating stress that cracks the interface over time.

This is more than a materials science puzzle. It directly impacts the cost and reliability of EVs. If solid-state batteries can’t consistently deliver thousands of charge cycles, they won’t replace current lithium-ion technology.

Electrolyte Limitations: A Secondary Problem

The summit also acknowledged that solid electrolytes themselves present hurdles. Oxides are too brittle, sulfides and chlorides require external pressure, which complicates mass production. While low-modulus polymers and interface-friendly electrolytes are being explored, they don’t solve the core problem: even the best electrolyte can’t compensate for a poorly designed cathode.

China’s Battery Giants Lead the Way

Major Chinese manufacturers—CATL, BYD, and Eve Energy—are already integrating cathode and electrolyte development, aggressively patenting new designs. They’re also investing in advanced manufacturing techniques like dry electrodes and co-sintering to reduce costs and streamline production.

A Dual-Track Future

The industry is diverging into three key approaches:

- High-End EVs: Polymer electrolytes paired with high-nickel or lithium-rich cathodes for maximum performance.

- Mass-Market EVs: LiFePO4 systems prioritizing safety and affordability.

- Specialized Applications: Sulfide electrolytes combined with sulfur cathodes for niche use cases.

“Cathode material innovation is the ‘bull’s nose’ of industrial solid-state batteries.”

The conclusion is clear: while electrolytes matter, the future of solid-state batteries rests squarely on breakthroughs in cathode technology. China is positioning itself to lead this sector by aggressively pursuing both material science and scalable manufacturing.